Direct Factory Price Hammer Crusher Mining Equipment For Stone Limestone Crushing

Подробная информация о продукте:

| Место происхождения: | КИТАЙ |

| Фирменное наименование: | TONTEN |

| Номер модели: | TT-HC |

Оплата и доставка Условия:

| Количество мин заказа: | 1 набор |

|---|---|

| Цена: | Подлежит обсуждению |

| Упаковывая детали: | Деревянная упаковка или на заказ |

| Время доставки: | 5-10 дней |

| Условия оплаты: | T/T. |

| Поставка способности: | 1-2 комплекта около 10 дней |

|

Подробная информация |

|||

| Клинок материал: | Сплава Сталь | Цвет: | по заказу клиента |

|---|---|---|---|

| Функции: | Высокая эффективность, низкий шум, легкая работа | Тип дробилки: | Мобильная дробилка с молотком |

| Сила: | Мотор, двигатель дизеля | Материалы для дробления: | известняк, шлак, кокс, уголь и другие материалы |

| Приложение: | Горнодобывающая промышленность/строительные материалы/химическая промышленность | Преимущества: | Высокая эффективность дробления |

| Выделить: | hammer crusher for limestone crushing,direct factory price crusher machine,mining equipment stone crusher |

||

Характер продукции

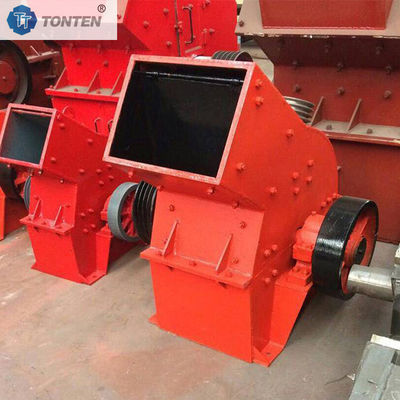

Direct Factory Price Hammer Crusher Mining Equipment For Stone Limestone Crushing

As a high-efficiency crushing equipment widely used in industrial production, the Hammer Crusher is designed to crush various materials through the high-speed impact of hammerheads. Its core working principle is simple yet effective: when materials enter the crushing chamber, they are repeatedly hit, impacted, and sheared by the rotating hammerheads (driven by a motor), then crushed into particles of the required size. The qualified materials are discharged through the screen at the bottom, while larger particles are retained for further crushing until they meet the standard.

Structure Introduction:

1.Shell 2.Motor 3.Count bar 4.Strike plate 5.Elastic coupling

Hammer Crusher Mining Equipment Main Parameters

| Item | Parameters |

| Model | 600*400 |

| Speed(r/min) | 1000 |

| Feed port size(mm) | 295*450 |

| Discharge size(mm) | 15 |

| Capacity(t/hour) | 10-12 |

| Power(kw) | 18.5 |

| Crushing materials | coal/salt/brick/limestone |

Hammer Crusher Mining Equipment More Detailed Informations

![]()

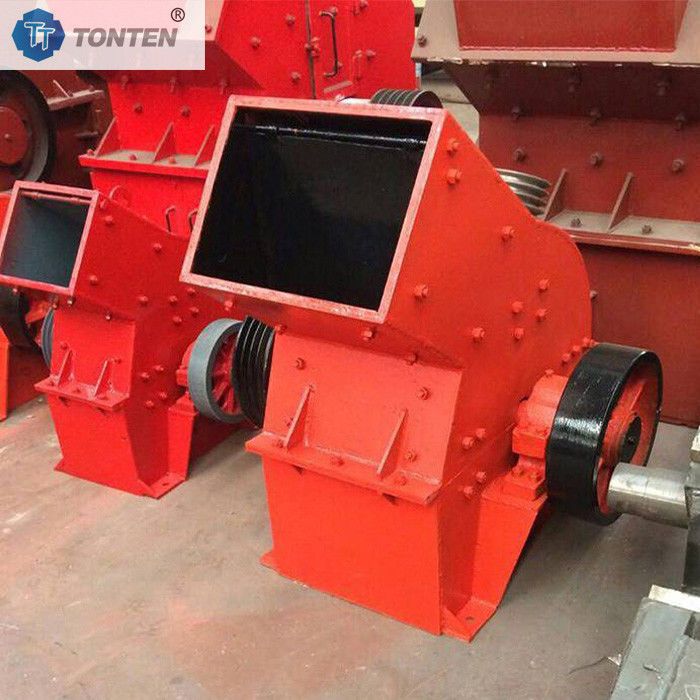

Hammer Crusher Mining Equipment Core Features

① Intuitive and efficient crushing principle: The rotor drives the hammers to rotate at high speed, generating strong impacts on the material entering the crushing chamber. This is combined with the material's collision and rebound with the liner and screen plates to achieve rapid crushing.

② Simple and compact structural design: The core consists of the casing, rotor, hammers, screen plates, and other components.

③ Flexible and adjustable output particle size: By adjusting the gap between the hammers and the screen plates and replacing screen plates with different apertures, coarse, medium, and fine crushing can be achieved.

④ Wide range of applicable materials: Excellent crushing performance for medium to low hardness materials such as limestone, coal, gypsum, shale, construction waste, and brick and tile clay.

⑤ High operational stability: The hammers and liners are made of wear-resistant materials (such as high-manganese steel and alloys).

Hammer Crusher Mining Equipment Main Applications

① Mining Industry: Used for crushing ores such as limestone, dolomite, and shale to provide raw materials for mineral processing and building materials production. Commonly used in primary and secondary crushing lines at small and medium-sized mines, it can also serve as pre-processing equipment at large mines.

② Building Materials Industry:

In cement production, it crushes raw materials such as limestone, clay, and gypsum to meet the particle size requirements for raw material grinding.

In sand and gravel aggregate production, it crushes rock and pebbles into sand and gravel of varying sizes for use in concrete mixing, road paving, and building masonry.

③ Coal Industry: Crushes raw coal for use as fuel in thermal power plants and in coal washing and processing.

④ Chemical and Other Industries: It provides basic materials for fertilizer and chemical product production. It is also suitable for crushing ceramic raw materials and wood waste.