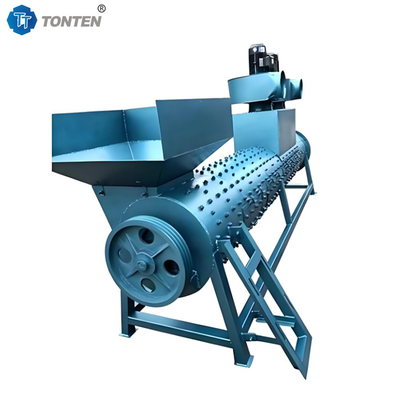

Высокоэффективная система интеллектуального управления с низким уровнем потребления пластмассовых материалов

Подробная информация о продукте:

| Место происхождения: | Китай |

| Фирменное наименование: | TONTEN |

| Номер модели: | TT-SLP01 |

Оплата и доставка Условия:

| Количество мин заказа: | 1SET |

|---|---|

| Цена: | Подлежит обсуждению |

| Упаковывая детали: | контейнер |

| Время доставки: | 10-15 рабочих дней |

| Условия оплаты: | T/T |

| Поставка способности: | 20 единиц в месяц |

|

Подробная информация |

|||

| Применение: | Переработка | Операция: | Легко. |

|---|---|---|---|

| Температура: | Проконтролированный | Поддерживающее оборудование: | Двигатель, редуктор, вал лезвия, лезвие |

| Грузовые материалы: | Пластмасса PVC | Конечный продукт: | Пластмассовые гранулы |

| Влияние: | Хорошо. | Пункты продажи: | Легкий к деятельности |

| Выделить: | Линия переработки пластмасс для дробления и переработки пластмасс с низким потреблением,Интеллектуальная линия переработки пластмассовых дробилок,Высокоэффективная линия переработки пластмасс для дробления |

||

Характер продукции

Высокоэффективная система интеллектуального управления с низким уровнем потребления пластмассовых материалов

Введение продукта

Производственная линия для дробления и переработки пластмасс представляет собой автоматизированное оборудование, включающее сортировку, дробление, очистку, сушку и гранулирование.который может обрабатывать различные термопластические отходы; система очистки и сушки обеспечивает высокую чистоту путем очистки барабана, очистки на трении и сушки на горячем воздухе;Система гранулирования оснащена точным устройством контроля температуры для производства однородных переработанных гранул.; электрическая система управления поддерживает одноключевое начало-остановку и предупреждение о неисправности.и мощность может быть адаптирована в соответствии с характеристиками сырья и условиями участка., и он широко используется в области производства переработанных пластмасс, модификации обработки и промышленных парков экономики переработки.

Преимущества продукта

Прочное и надежное обеспечение качества

Основные компоненты изготовлены из высококачественных износостойких материалов, таких как лезвия дробителей из высокопрочных сплавов,и конструкция предназначена для долговечности и может выдерживать длительную работу с высокой нагрузкой.Модульная структура оборудования облегчает ежедневное обслуживание и замену деталей, сокращает время простоя, обеспечивает стабильную работу производственной линии и снижает затраты на обслуживание и беспокойства пользователей..

Устойчивость, отвечающая требованиям окружающей среды

Профессиональные устройства для очистки пыли и сточных вод оснащены в процессе дробления и очистки, эффективно снижая выбросы пыли и загрязнение сточных вод,в соответствии с национальными и международными экологическими стандартамиТехнология переработки воды и энергосберегающая конструкция еще больше снижают потребление энергии и ресурсов.Помощь пользователям в создании экологически чистой модели производства, отвечающей потребностям глобальной циркулярной экономики и политики охраны окружающей среды.

Устойчивое производство с высокой добавленной стоимостью

Благодаря точному контролю температуры и контроля процесса система гранулирования производит гранулы из переработанного пластика с равномерным размером частиц и низким содержанием примесей,качество которого может быть непосредственно использовано для замены новых материалов в формовочной инжекции, пленки и другие сценарии обработки, помогающие пользователю достичь высокой добавленной стоимости использования отходов пластика,и повышение добавленной стоимости продукта и его конкурентоспособности на рынке.

Принцип работы

Оборудование должно быть помещено в проветриваемое положение, регулярно смазывать подшипники и проверять крепежные элементы; перед запуском ручно вращать ротор, чтобы убедиться в отсутствии аномалий.избегать перегрузки; поддерживать равномерное питание материала во время работы и немедленно останавливать машину при обнаружении каких-либо вибраций, ненормального шума или ненормальной температуры;регулярно проверяйте остроту резки и эластичность ремня, и регулируйте соответствующий разрыв при замене резки; отключите питание во время технического обслуживания, чтобы обеспечить безопасную работу.

Список параметров

| Единая производственная мощность | 1000-1500 кг/ч | Степень раздавливания | Средний дробилка | Разрушающая изящество | Среднее дробление |

| Сила | 3700 Вт | Размер питающей частицы | 900 | Применимое звездное рейтинги | Пять. |

| Содержание влаги | 20% | Твердость материала | 30 | Принцип | Разрушитель пластмасс |

| Вес | 1990 кг | Скорость | 18 оборотов в минуту | Импортируемый или нет | Нет, нет. |

| Гарантийный период | Однолетняя гарантия | Производственная мощность | 1000-1500 кг/ч | Напряжение питания | 380 В |

![]()